Conversion of Lignocellulosic Amazonian Biomass into Biochar: Applications in Supercapacitors and Catalysts: Review.

DOI:

https://doi.org/10.34024/jsse.2024.v2.19345Keywords:

biomass, biochar, supercapacitor, catalystAbstract

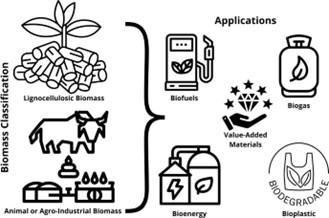

This article explores the valorization of Amazonian biomass through its conversion into biochar, addressing the main technologies involved and their applications in supercapacitors and catalysts. The conversion of biomass into biochar is highlighted as a sustainable strategy for utilizing agroindustrial waste and generating high-value materials. The article reviews relevant technologies for this conversion, including hydrothermal carbonization, chemical activation, and pyrolysis, emphasizing their impacts on creating biochar with adjustable properties such as high surface area and controlled porosity. It also reviews recent studies investigating the valorization of Amazonian biomass for these specific applications, highlighting the advances made. Finally, future perspectives are discussed, including the exploration of new Amazonian biomass sources and the optimization of conversion techniques to expand biochar applications and promote technological innovation and sustainability in the Amazon region.

References

Tursi, A. (2019). A review on biomass: importance, chemistry, classification, and conversion. Biofuel Research Journal, 6(2), 962–979. https://doi.org/10.18331/BRJ2019.6.2.3

Sherwood, J. (2020). The significance of biomass in a circular economy. Bioresource Technology, 300, 122755. https://doi.org/10.1016/j.biortech.2020.122755

Yadav, B., Atmakuri, A., Chavan, S., Tyagi, R. D., Drogui, P., & Pilli, S. (2021). Role of Bioeconomy in Circular Economy. In Biomass, Biofuels, Biochemicals (pp. 163–195). Elsevier. https://doi.org/10.1016/B978-0-12-821878-5.00022-2

Amalina, F., Razak, A. S. A., Krishnan, S., Sulaiman, H., Zularisam, A. W., & Nasrullah, M. (2022). Biochar production techniques utilizing biomass waste-derived materials and environmental applications – A review. Journal of Hazardous Materials Advances, 7, 100134. https://doi.org/10.1016/j.hazadv.2022.100134

Araujo, R. O., Ribeiro, F. C. P., Santos, V. O., Lima, V. M. R., Santos, J. L., Vilaça, J. E. S., Chaar, J. S., Falcão, N. P. S., Pohlit, A. M., & de Souza, L. K. C. (2022). Renewable Energy from Biomass: an Overview of the Amazon Region. BioEnergy Research, 15(2), 834–849. https://doi.org/10.1007/s12155-021-10308-x

Allohverdi, T., Mohanty, A. K., Roy, P., & Misra, M. (2021). A Review on Current Status of Biochar Uses in Agriculture. Molecules, 26(18), 5584. https://doi.org/10.3390/molecules26185584

Jagadeesh, N., & Sundaram, B. (2023). Adsorption of Pollutants from Wastewater by Biochar: A Review. Journal of Hazardous Materials Advances, 9, 100226. https://doi.org/10.1016/j.hazadv.2022.100226

Lee, J., Kim, K.-H., & Kwon, E. E. (2017). Biochar as a Catalyst. Renewable and Sustainable Energy Reviews, 77, 70–79. https://doi.org/10.1016/j.rser.2017.04.002

Popp, J., Kovács, S., Oláh, J., Divéki, Z., & Balázs, E. (2021). Bioeconomy: Biomass and biomass-based energy supply and demand. New Biotechnology, 60, 76–84. https://doi.org/10.1016/j.nbt.2020.10.004

Casau, M., Dias, M. F., Matias, J. C. O., & Nunes, L. J. R. (2022). Residual Biomass: A Comprehensive Review on the Importance, Uses and Potential in a Circular Bioeconomy Approach. Resources, 11(4), 35. https://doi.org/10.3390/resources11040035

Mumtaz, M., Baqar, Z., Hussain, N., Afifa, Bilal, M., Azam, H. M. H., Baqir, Q., & Iqbal, H. M. N. (2022). Application of nanomaterials for enhanced production of biodiesel, biooil, biogas, bioethanol, and biohydrogen via lignocellulosic biomass transformation. Fuel, 315, 122840. https://doi.org/10.1016/j.fuel.2021.122840

Rajesh Banu, J., Preethi, Kavitha, S., Tyagi, V. K., Gunasekaran, M., Karthikeyan, O. P., & Kumar, G. (2021). Lignocellulosic biomass based biorefinery: A successful platform towards circular bioeconomy. Fuel, 302, 121086. https://doi.org/10.1016/j.fuel.2021.121086

Velvizhi, G., Balakumar, K., Shetti, N. P., Ahmad, E., Kishore Pant, K., & Aminabhavi, T. M. (2022). Integrated biorefinery processes for conversion of lignocellulosic biomass to value added materials: Paving a path towards circular economy. Bioresource Technology, 343, 126151. https://doi.org/10.1016/j.biortech.2021.126151

Bonechi, C., Consumi, M., Donati, A., Leone, G., Magnani, A., Tamasi, G., & Rossi, C. (2017). Biomass. In Bioenergy Systems for the Future (pp. 3–42). Elsevier. https://doi.org/10.1016/B978-0-08-101031-0.00001-6

Matveeva, V. G., & Bronstein, L. M. (2022). From renewable biomass to nanomaterials: Does biomass origin matter? Progress in Materials Science, 130, 100999. https://doi.org/10.1016/j.pmatsci.2022.100999

Tursi, A. (2019). A review on biomass: importance, chemistry, classification, and conversion. Biofuel Research Journal, 6(2), 962–979. https://doi.org/10.18331/BRJ2019.6.2.3

Onokwai, A. O., Ajisegiri, E. S. A., Okokpujie, I. P., Ibikunle, R. A., Oki, M., & Dirisu, J. O. (2022). Characterization of lignocellulose biomass based on proximate, ultimate, structural composition, and thermal analysis. Materials Today: Proceedings, 65, 2156–2162. https://doi.org/10.1016/j.matpr.2022.05.313

Yousuf, A., Pirozzi, D., & Sannino, F. (2020). Fundamentals of lignocellulosic biomass. In Lignocellulosic Biomass to Liquid Biofuels (pp. 1–15). Elsevier. https://doi.org/10.1016/B978-0-12-815936-1.00001-0

Gupta, M., Savla, N., Pandit, C., Pandit, S., Gupta, P. K., Pant, M., Khilari, S., Kumar, Y., Agarwal, D., Nair, R. R., Thomas, D., & Thakur, V. K. (2022). Use of biomass-derived biochar in wastewater treatment and power production: A promising solution for a sustainable environment. Science of The Total Environment, 825, 153892. https://doi.org/10.1016/j.scitotenv.2022.153892

Nobre, J. R. C., Queiroz, L. S., Castro, J. P., Pego, M. F. F., Hugen, L. N., Costa, C. E. F. da, Pardauil, J. de J. R., Nascimento, L. A. S. do, Rocha Filho, G. N. da, Zamian, J. R., Souza, E. C. de, & Bianchi, M. L. (2023). Potential of agro-industrial residues from the Amazon region to produce activated carbon. Heliyon, 9(7), e17189. https://doi.org/10.1016/j.heliyon.2023.e17189

IBGE, Brazilian Institute of Geography and Statistics.< https://www.ibge.gov.br/explica/producao-agropecuaria/guarana/br /> (accessed April/2024)

Freitas, L. C., Barbosa, J. R., da Costa, A. L. C., Bezerra, F. W. F., Pinto, R. H. H., & Carvalho Junior, R. N. de. (2021). From waste to sustainable industry: How can agro-industrial wastes help in the development of new products? Resources, Conservation and Recycling, 169, 105466. https://doi.org/10.1016/j.resconrec.2021.105466

Babu, S., Singh Rathore, S., Singh, R., Kumar, S., Singh, V. K., Yadav, S. K., Yadav, V., Raj, R., Yadav, D., Shekhawat, K., & Ali Wani, O. (2022). Exploring agricultural waste biomass for energy, food and feed production and pollution mitigation: A review. Bioresource Technology, 360, 127566. https://doi.org/10.1016/j.biortech.2022.127566

Clauser, N. M., González, G., Mendieta, C. M., Kruyeniski, J., Area, M. C., & Vallejos, M. E. (2021). Biomass Waste as Sustainable Raw Material for Energy and Fuels. Sustainability, 13(2), 794. https://doi.org/10.3390/su13020794

Paunovic, O., Pap, S., Maletic, S., Taggart, M. A., Boskovic, N., & Turk Sekulic, M. (2019). Ionisable emerging pharmaceutical adsorption onto microwave functionalised biochar derived from novel lignocellulosic waste biomass. Journal of Colloid and Interface Science, 547, 350–360. https://doi.org/10.1016/j.jcis.2019.04.011

Monteiro, E., & Ferreira, S. (2022). Biomass Waste for Energy Production. Energies, 15(16), 5943. https://doi.org/10.3390/en15165943

Sajjadi, B., Chen, W.-Y., & Egiebor, N. O. (2019). A comprehensive review on physical activation of biochar for energy and environmental applications. Reviews in Chemical Engineering, 35(6), 735–776. https://doi.org/10.1515/revce-2017-0113

Venkatachalam, C. D., Sekar, S., Sengottian, M., Ravichandran, S. R., & Bhuvaneshwaran, P. (2023). A critical review of the production, activation, and morphological characteristic study on functionalized biochar. Journal of Energy Storage, 67, 107525. https://doi.org/10.1016/j.est.2023.107525

Li, Y., Xing, B., Ding, Y., Han, X., & Wang, S. (2020). A critical review of the production and advanced utilization of biochar via selective pyrolysis of lignocellulosic biomass. Bioresource Technology, 312, 123614. https://doi.org/10.1016/j.biortech.2020.123614

Panwar, N. L., & Pawar, A. (2022). Influence of activation conditions on the physicochemical properties of activated biochar: a review. Biomass Conversion and Biorefinery, 12(3), 925–947. https://doi.org/10.1007/s13399-020-00870-3

Jedynak, K., & Charmas, B. (2023). Adsorption properties of biochars obtained by KOH activation. Adsorption. https://doi.org/10.1007/s10450-023-00399-7

Thue, P. S., Lima, D. R., Lima, E. C., Teixeira, R. A., dos Reis, G. S., Dias, S. L. P., & Machado, F. M. (2022). Comparative studies of physicochemical and adsorptive properties of biochar materials from biomass using different zinc salts as activating agents. Journal of Environmental Chemical Engineering, 10(3), 107632. https://doi.org/10.1016/j.jece.2022.107632

Yang, H., Chen, P., Chen, W., Li, K., Xia, M., Xiao, H., Chen, X., Chen, Y., Wang, X., & Chen, H. (2022). Insight into the formation mechanism of N, P co-doped mesoporous biochar from H3PO4 activation and NH3 modification of biomass. Fuel Processing Technology, 230, 107215. https://doi.org/10.1016/j.fuproc.2022.107215

Adeniyi, A. G., Abdulkareem, S. A., Iwuozor, K. O., Ogunniyi, S., Abdulkareem, M. T., Emenike, E. C., & Sagboye, P. A. (2022). Effect of salt impregnation on the properties of orange albedo biochar. Cleaner Chemical Engineering, 3, 100059. https://doi.org/10.1016/j.clce.2022.100059

Abu-Danso E, Bagheri A, Bhatnagar A (2019) Facile functionalization of cellulose from discarded cigarette butts for the removal of diclofenac from water. Carbohyd Polym 219:46–55. https://doi.org/10.1016/j.carbpol.2019.04.090

Mendaros CM, Go AW, Nietes WJT, Gollem BEJO, Cabatingan LK (2020) Direct sulfonation of cacao shell to synthesize a solid acid catalyst for the esterification of oleic acid with methanol. Renew Energy 152:320–330. https://doi.org/10.1016/j.renene.2020.01.066

Mukhtar A, Saqib S, Lin H, Shah MUH, Ullah S, Younas M, Bokhari A (2022) Current status and challenges in the heterogeneous catalysis for biodiesel production. Renew Sustain Energy Rev 157:112012. https://doi.org/10.1016/j.rser.2021.112012

Zhang, J., Gu, M., & Chen, X. (2023). Supercapacitors for renewable energy applications: A review. Micro and Nano Engineering, 21, 100229. https://doi.org/10.1016/j.mne.2023.100229

Yin, J., Zhang, W., Alhebshi, N. A., Salah, N., & Alshareef, H. N. (2020). Synthesis Strategies of Porous Carbon for Supercapacitor Applications. Small Methods, 4(3). https://doi.org/10.1002/smtd.201900853

Wang, Y., Xu, T., Liu, K., Zhang, M., Cai, X., & Si, C. (2023). Biomass‐based materials for advanced supercapacitor: principles, progress, and perspectives. Aggregate. https://doi.org/10.1002/agt2.428

Sharma, S., & Chand, P. (2023). Supercapacitor and electrochemical techniques: A brief review. Results in Chemistry, 5, 100885. https://doi.org/10.1016/j.rechem.2023.100885

Wang, Y., Xu, T., Liu, K., Zhang, M., Cai, X., & Si, C. (2023). Biomass‐based materials for advanced supercapacitor: principles, progress, and perspectives. Aggregate. https://doi.org/10.1002/agt2.428

Vijayakumar, M., Bharathi Sankar, A., Sri Rohita, D., Rao, T. N., & Karthik, M. (2019). Conversion of Biomass Waste into High Performance Supercapacitor Electrodes for Real-Time Supercapacitor Applications. ACS Sustainable Chemistry & Engineering, 7(20), 17175–17185. https://doi.org/10.1021/acssuschemeng.9b03568

Wang, Y., Zhang, L., Hou, H., Xu, W., Duan, G., He, S., Liu, K., & Jiang, S. (2021). Recent progress in carbon-based materials for supercapacitor electrodes: a review. Journal of Materials Science, 56(1), 173–200. https://doi.org/10.1007/s10853-020-05157-6

Yin, J., Zhang, W., Alhebshi, N. A., Salah, N., & Alshareef, H. N. (2020). Synthesis Strategies of Porous Carbon for Supercapacitor Applications. Small Methods, 4(3). https://doi.org/10.1002/smtd.201900853

Ismanto, A. E., Wang, S., Soetaredjo, F. E., & Ismadji, S. (2010). Preparation of capacitor’s electrode from cassava peel waste. Bioresource Technology, 101(10), 3534–3540. https://doi.org/10.1016/j.biortech.2009.12.123

Sk, M. M., Pradhan, P., Patra, B. K., & Guria, A. K. (2023). Green biomass derived porous carbon materials for electrical double-layer capacitors (EDLCs). Materials Today Chemistry, 30, 101582. https://doi.org/10.1016/j.mtchem.2023.101582

Jiang, B., Cao, L., Yuan, Q., Ma, Z., Huang, Z., Lin, Z., & Zhang, P. (2022). Biomass Straw-Derived Porous Carbon Synthesized for Supercapacitor by Ball Milling. Materials, 15(3), 924. https://doi.org/10.3390/ma15030924

Mohammed, A. A., Chen, C., & Zhu, Z. (2019). Low-cost, high-performance supercapacitor based on activated carbon electrode materials derived from baobab fruit shells. Journal of Colloid and Interface Science, 538, 308–319. https://doi.org/10.1016/j.jcis.2018.11.103

Zhang, Y., Li, X., Li, Z., & Yang, F. (2024). Evaluation of electrochemical performance of supercapacitors from equivalent circuits through cyclic voltammetry and galvanostatic charge/discharge. Journal of Energy Storage, 86, 111122. https://doi.org/10.1016/j.est.2024.111122

Pedro Aguiar dos Santos, J., Cesar Rufino, F., Yutaka Ota, J. I., Fernandes, R. C., Vicentini, R., Pagan, C. J. B., Morais Da Silva, L., & Zanin, H. (2023). Best practices for electrochemical characterization of supercapacitors. Journal of Energy Chemistry, 80, 265–283. https://doi.org/10.1016/j.jechem.2022.12.034

Devillers, N., Jemei, S., Péra, M.-C., Bienaimé, D., & Gustin, F. (2014). Review of characterization methods for supercapacitor modelling. Journal of Power Sources, 246, 596–608. https://doi.org/10.1016/j.jpowsour.2013.07.116

Sahoo, B. B., Pandey, V. S., Dogonchi, A. S., Thatoi, D. N., Nayak, N., & Nayak, M. K. (2023). Synthesis, characterization and electrochemical aspects of graphene based advanced supercapacitor electrodes. Fuel, 345, 128174. https://doi.org/10.1016/j.fuel.2023.128174

Randviir, E. P., & Banks, C. E. (2022). A review of electrochemical impedance spectroscopy for bioanalytical sensors. Analytical Methods, 14(45), 4602–4624. https://doi.org/10.1039/D2AY00970F

Lazanas, A. Ch., & Prodromidis, M. I. (2023). Electrochemical Impedance Spectroscopy─A Tutorial. ACS Measurement Science Au, 3(3), 162–193. https://doi.org/10.1021/acsmeasuresciau.2c00070

Kanoun, O. (2018). Impedance spectroscopy advances and future trends: A comprehensive review. In Impedance Spectroscopy (pp. 1–22). De Gruyter. https://doi.org/10.1515/9783110558920-001

de Souza, L. K. C., Martins, J. C., Oliveira, D. P., Ferreira, C. S., Gonçalves, A. A. S., Araujo, R. O., da Silva Chaar, J., Costa, M. J. F., Sampaio, D. v., Passos, R. R., & Pocrifka, L. A. (2020). Hierarchical porous carbon derived from acai seed biowaste for supercapacitor electrode materials. Journal of Materials Science: Materials in Electronics, 31(15), 12148–12157. https://doi.org/10.1007/s10854-020-03761-5

Thomaz, K. T. C., Queiroz, L. S., Faial, K. D. C. F., Zamian, J. R., do Nascimento, L. A. S., Rocha Filho, G. N., de Souza, L. K. C., & da Costa, C. E. F. (2023). Removal of Fe and Mn ions from groundwater using activated carbon obtained from waste products of Brazil nut and andiroba cultivation in the Amazon region. Sustainable Materials and Technologies, 38, e00737. https://doi.org/10.1016/j.susmat.2023.e00737

Serafin, J., Ouzzine, M., Xing, C., el Ouahabi, H., Kamińska, A., & Sreńscek-Nazzal, J. (2022). Activated carbons from the Amazonian biomass andiroba shells applied as a CO2 adsorbent and a cheap semiconductor material. Journal of CO2 Utilization, 62, 102071. https://doi.org/10.1016/j.jcou.2022.102071

Umpierres, C. S., Thue, P. S., Lima, E. C., Reis, G. S. dos, de Brum, I. A. S., Alencar, W. S. de, Dias, S. L. P., & Dotto, G. L. (2018). Microwave-activated carbons from tucumã ( Astrocaryum aculeatum ) seed for efficient removal of 2-nitrophenol from aqueous solutions. Environmental Technology, 39(9), 1173–1187. https://doi.org/10.1080/09593330.2017.1323957

Castro, P. M. de, Regina Ferrarini, S., Rimoli, M. da S. F., Merlo, A. A., Nogueira, R. M., & Pires, E. M. (2023). Preparation and characterization of steam and CO2 activated carbon from Brazil nut shell. Bioscience Journal, 39, e39054. https://doi.org/10.14393/BJ-v39n0a2023-64438

Teixeira Alves, A., de Andrade Miranda, I. P., José Lasmar, D., & Costa, A. (2023). Viabilidade econômica do carvão ativado obtido do ouriço da castanha-do-brasil (bertholletia excelsa). Future Studies Research Journal: Trends and Strategies, 16(1), e0765. https://doi.org/10.24023/FutureJournal/2175-5825/2024.v16i1.765

dos Santos, L. N., Porto, C. E., Bulla, M. K., Batistela, V. R., & Barros, B. C. B. (2021). Peach palm and cassava wastes as biosorbents of tartrazine yellow dye and their application in industrial effluent. Scientia Plena, 17(5). https://doi.org/10.14808/sci.plena.2021.054201

Mafra, E. R. M. L., de Paula Protásio, T., Bezerra Bezerra, J., Pedroza, M. M., Barbosa, D. B., Viana, M. F., de Souza, T. M., & Bufalino, L. (2024). Comparative analysis of seed biomass from Amazonian fruits for activated carbon production. Biomass Conversion and Biorefinery, 14(10), 11279–11293. https://doi.org/10.1007/s13399-022-03348-6

Saucier, C., Adebayo, M. A., Lima, E. C., Prola, L. D. T., Thue, P. S., Umpierres, C. S., Puchana‐Rosero, M. J., & Machado, F. M. (2015). Comparison of a Homemade Bacuri Shell Activated Carbon With Carbon Nanotubes for Food Dye Removal. CLEAN – Soil, Air, Water, 43(10), 1389–1400. https://doi.org/10.1002/clen.201400669

Martins, T. A., de Sá, F. P., Pereira, J., & de Oliveira, T. F. (2024). Use of murici (Byrsonima crassifolia) and jabuticaba (Plinia cauliflora) residues in the preparation of porous materials: Effect of pH on the adsorption efficiency of the contaminants phenol, diethylphthalate and amoxicillin. Desalination and Water Treatment, 317, 100110. https://doi.org/10.1016/j.dwt.2024.100110

Nobre, J. R. C., Queiroz, L. S., Castro, J. P., Pego, M. F. F., Hugen, L. N., Costa, C. E. F. da, Pardauil, J. de J. R., Nascimento, L. A. S. do, Rocha Filho, G. N. da, Zamian, J. R., Souza, E. C. de, & Bianchi, M. L. (2023). Potential of agro-industrial residues from the Amazon region to produce activated carbon. Heliyon, 9(7), e17189. https://doi.org/10.1016/j.heliyon.2023.e17189

Lobo, W. V., Loureiro Paes, O. A. da R., Pinheiro, W., Soares, E. R., de Souza, M. P., dos Santos Sousa, A., Kumar, V., Iglauer, S., & de Freitas, F. A. (2024). Application of chemically modified waste tucumã (Astrocaryum aculeatum) seeds in the biosorption of methylene blue: kinetic and thermodynamic parameters. Environmental Science and Pollution Research, 31(23), 34097–34111. https://doi.org/10.1007/s11356-024-33517-1

MARASCA, N., BRITO, M. R., RAMBO, M. C. D., PEDRAZZI, C., SCAPIN, E., & RAMBO, M. K. D. (2022). Analysis of the potential of cupuaçu husks (Theobroma grandiflorum) as raw material for the synthesis of bioproducts and energy generation. Food Science and Technology, 42. https://doi.org/10.1590/fst.48421

Mukhtar A, Saqib S, Lin H, Shah MUH, Ullah S, Younas M, Bokhari A (2022) Current status and challenges in the heterogeneous catalysis for biodiesel production. Renew Sustain Energy Rev 157:112012. https://doi.org/10.1016/j.rser.2021.112012

Nata IF, Putra MD, Irawan C, Lee CK (2017) Catalytic performance of sulfonated carbon-based solid acid catalyst on esterification of waste cooking oil for biodiesel production. J Environ Chem Eng 5(3):2171–2175. https://doi.org/10.1016/j.jece.2017.04.029

Mendaros CM, Go AW, Nietes WJT, Gollem BEJO, Cabatingan LK (2020) Direct sulfonation of cacao shell to synthesize a solid acid catalyst for the esterification of oleic acid with methanol. Renew Energy 152:320–330. https://doi.org/10.1016/j.renene.2020.01.066

Santos EM, de Carvalho Teixeira AP, da Silva FG, Cibaka TE, Araújo MH, Oliveira WXC, Lago RM (2015) New heterogeneous catalyst for the esterification of fatty acid produced by surface aromatization/sulfonation of oilseed cake. Fuel 150:408–414. https://doi.org/10.1016/j.fuel.2015.02.027

Sun H, La P, Yang R, Zhu Z, Liang W, Yang B, Deng W (2017) Innovative nanoporous carbons with ultrahigh uptakes for capture and reversible storage of CO2 and volatile iodine. J Hazard Mater 321:210–217. https://doi.org/10.1016/j.jhazmat.2016.09.015

Espíndola, J. C., & Vilar, V. J. P. (2020). Innovative light-driven chemical/catalytic reactors towards contaminants of emerging concern mitigation: A review. Chemical Engineering Journal, 394, 124865. https://doi.org/10.1016/j.cej.2020.124865

Laguna, O. H., Lietor, P. F., Godino, F. J. I., & Corpas-Iglesias, F. A. (2021). A review on additive manufacturing and materials for catalytic applications: Milestones, key concepts, advances and perspectives. Materials & Design, 208, 109927. https://doi.org/10.1016/j.matdes.2021.109927

Mohiddin, M. N. bin, Tan, Y. H., Seow, Y. X., Kansedo, J., Mubarak, N. M., Abdullah, M. O., Chan, Y. S., & Khalid, M. (2021). Evaluation on feedstock, technologies, catalyst and reactor for sustainable biodiesel production: A review. Journal of Industrial and Engineering Chemistry, 98, 60–81. https://doi.org/10.1016/j.jiec.2021.03.036

Iwanow, M., Gärtner, T., Sieber, V., & König, B. (2020). Activated carbon as catalyst support: precursors, preparation, modification and characterization. Beilstein Journal of Organic Chemistry, 16, 1188–1202. https://doi.org/10.3762/bjoc.16.104

Krishna, D. N. G., & Philip, J. (2022). Review on surface-characterization applications of X-ray photoelectron spectroscopy (XPS): Recent developments and challenges. Applied Surface Science Advances, 12, 100332. https://doi.org/10.1016/j.apsadv.2022.100332

ALI, R., ASLAM, Z., SHAWABKEH, R. A., ASGHAR, A., & HUSSEIN, I. A. (2020). BET, FTIR, and RAMAN characterizations of activated carbon from wasteoil fly ash. TURKISH JOURNAL OF CHEMISTRY, 44(2), 279–295. https://doi.org/10.3906/kim-1909-20

Mendonça, I. M., Paes, O. A. R. L., Maia, P. J. S., Souza, M. P., Almeida, R. A., Silva, C. C., Duvoisin, S., & de Freitas, F. A. (2019). New heterogeneous catalyst for biodiesel production from waste tucumã peels (Astrocaryum aculeatum Meyer): Parameters optimization study. Renewable Energy, 130, 103–110. https://doi.org/10.1016/j.renene.2018.06.059

Araujo, R. O., Santos, V. O., Ribeiro, F. C. P., Chaar, J. da S., Falcão, N. P. S., & de Souza, L. K. C. (2021). One-step synthesis of a heterogeneous catalyst by the hydrothermal carbonization of acai seed. Reaction Kinetics, Mechanisms and Catalysis, 134(1), 199–220. https://doi.org/10.1007/s11144-021-02059-9

Ribeiro, T. S., Gonçalves, M. A., da Rocha Filho, G. N., & da Conceição, L. R. V. (2023). Functionalized Biochar from the Amazonian Residual Biomass Murici Seed: An Effective and Low-Cost Basic Heterogeneous Catalyst for Biodiesel Synthesis. Molecules, 28(24), 7980. https://doi.org/10.3390/molecules28247980

Bastos, R. R. C., da Luz Corrêa, A. P., da Luz, P. T. S., da Rocha Filho, G. N., Zamian, J. R., & da Conceição, L. R. V. (2020). Optimization of biodiesel production using sulfonated carbon-based catalyst from an amazon agro-industrial waste. Energy Conversion and Management, 205, 112457. https://doi.org/10.1016/j.enconman.2019.112457

Barros, S. de S., Nobre, F. X., Lobo, W. v., Duvoisin, S., de Souza, C. A. S., Herminio, V. L. de Q., Pereira, I. H., Silva, E. P., Iglauer, S., & de Freitas, F. A. (2024). Eco‐friendly biodiesel production using passion fruit peels and cupuaçu seeds: Catalyst development and process optimization. Biofuels, Bioproducts and Biorefining, 18(1), 96–112. https://doi.org/10.1002/bbb.2551

Ashok Kumar, S. S., Bashir, S., Pershaanaa, M., Kamarulazam, F., Saidi, N. M., Goh, Z. L., Ma, I. A. W., Kunjunee, V., Jamaluddin, A., Ramesh, K., Ramesh, S., Ramesh, S., & Manikam, R. (2023). A review on the recent progress of the plant-based porous carbon materials as electrodes for high-performance supercapacitors. Journal of Materials Science, 58(15), 6516–6555. https://doi.org/10.1007/s10853-023-08413-7

Khan, H. A., Tawalbeh, M., Aljawrneh, B., Abuwatfa, W., Al-Othman, A., Sadeghifar, H., & Olabi, A. G. (2024). A comprehensive review on supercapacitors: Their promise to flexibility, high temperature, materials, design, and challenges. Energy, 295, 131043. https://doi.org/10.1016/j.energy.2024.131043

Melo, V. M. e, Ferreira, G. F., & Fregolente, L. V. (2024). Sustainable catalysts for biodiesel production: The potential of CaO supported on sugarcane bagasse biochar. Renewable and Sustainable Energy Reviews, 189, 114042. https://doi.org/10.1016/j.rser.2023.114042

Ali Qamar, O., Jamil, F., Hussain, M., Al-Muhtaseb, A. H., Inayat, A., Waris, A., Akhter, P., & Park, Y.-K. (2023). Feasibility-to-applications of value-added products from biomass: Current trends, challenges, and prospects. Chemical Engineering Journal, 454, 140240. https://doi.org/10.1016/j.cej.2022.140240

Additional Files

Published

Issue

Section

Categories

How to Cite

Accepted 2024-11-04

Published 2024-12-03