Simulation of Anaerobic Treatment of Vinasse Generated from the Ethanol Production Process

DOI:

https://doi.org/10.34024/jsse.2025.v3.19682Keywords:

anaerobic treatment, Aspen Plus® software, simulation, vinasseAbstract

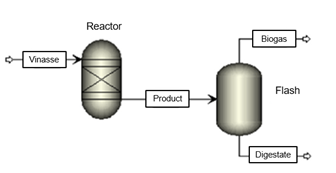

Vinasse is a primary byproduct of the sugarcane distillation process used in ethanol production. It is characterized by high concentrations of nitrogen, phosphorus, and sulfates, along with elevated levels of chemical oxygen demand (COD) and biochemical oxygen demand (BOD). If not managed properly, vinasse can have detrimental environmental effects, particularly on soil quality. Therefore, its treatment is essential not only to mitigate environmental risks but also to capitalize on potential energy and economic opportunities, such as bioenergy production and the generation of valuable byproducts. This study aimed to develop a virtual model using ASPEN PLUS® software for the treatment of vinasse generated in an ethanol biorefinery. The simulation achieved a theoretical organic matter removal efficiency of 100%, with biogas compositions consisting of 59 mol% methane, 32 mol% carbon dioxide, 5.5 mol% water, and 3 mol% nitrogen. Furthermore, this research contributes to the limited body of literature on vinasse treatment simulations, underscoring its potential as an eco-friendly and cost-effective waste management solution.

References

L. R. de Melo, B. Z. Demasi, M. N. de Araujo, R. C. Rogeri, L. C. Grangeiro, and L. T. Fuess, “Methane Production from Sugarcane Vinasse Biodigestion: An Efficient Bioenergy and Environmental Solution for the State of São Paulo, Brazil,” Methane, vol. 3, no. 2, pp. 314–330, 2024.

B. S. Moraes, M. Zaiat, and A. Bonomi, “Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: Challenges and perspectives,” Renewable and Sustainable Energy Reviews, vol. 44, pp. 888–903, 2015.

Statista Research Department, “Global ethanol fuel production 2023, by country,” Statista, May 14, 2024. Available: https://www.statista.com/statistics/281606/ethanol-production-in-selected-countries/.

A. do V. Borges, L. T. Fuess, I. Alves, P. Y. Takeda, and M. H. R. Z. Damianovic, “Co-digesting sugarcane vinasse and distilled glycerol to enhance bioenergy generation in biofuel-producing plants,” Energy Conversion and Management, vol. 250, p. 114897, 2021.

J. C. de Carvalho et al., “Biomethane production from sugarcane vinasse in a circular economy: Developments and innovations,” Fermentation, vol. 9, no. 4, p. 349, 2023.

L. C. Moreira, P. O. Borges, R. M. Cavalcante, and A. F. Young, “Simulation and economic evaluation of process alternatives for biogas production and purification from sugarcane vinasse,” Renewable and Sustainable Energy Reviews, vol. 163, p. 112532, 2022.

L. R. Ramos, G. Lovato, J. A. D. Rodrigues, and E. L. Silva, “Scale-up and energy estimations of single-and two-stage vinasse anaerobic digestion systems for hydrogen and methane production,” Journal of Cleaner Production, vol. 349, p. 131459, 2022.

A. C. Wilkie, K. J. Riedesel, and J. M. Owens, “Stillage characterization and anaerobic treatment of ethanol stillage from conventional and cellulosic feedstocks,” Biomass and Bioenergy, vol. 19, no. 1, pp. 63–102, 2000.

M. L. C. Elaiuy, A. L. Borrion, J. A. Stegemann, J. R. Pires, and E. A. A. Nour, “Optimizing large-scale covered in-ground anaerobic reactor (CIGAR) for sugarcane vines,” in Proceedings of the 6th International Conference on Engineering for Waste and Biomass Valorisation, Albi, France, 2016.

R. Gong and B. H. Lunelli, “Exergy analysis of biogas production from sugarcane vinasse,” BioEnergy Research, vol. 17, no. 2, pp. 1208–1216, 2024.

J. Lorenzo-Llanes, J. Pagés-Díaz, E. Kalogirou, and F. Contino, “Development and application in Aspen Plus of a process simulation model for the anaerobic digestion of vinasses in UASB reactors: Hydrodynamics and biochemical reactions,” Journal of Environmental Chemical Engineering, vol. 8, no. 2, p. 103540, 2020.

S. C. F. da Silva, Gaseificação de vinhaça em água supercrítica, Ph.D. dissertation, Univ. São Paulo, 2016.

T. P. M. Mattos, Modelagens do processo de gaseificação de fezes humanas, Ph.D. dissertation, Fed. Univ. Espírito Santo, Vitória, ES, 2017.

T. F. Xavier, Vinhaça in natura e biodigerida concentrada: Efeitos nas características químicas e bioquímicas do solo e no crescimento inicial da cana-de-açúcar, Master’s thesis, São Paulo State Univ., 2012.

M. T. de M. S. Gomes, K. S. Eça, and L. A. Viotto, “Concentração da vinhaça por microfiltração seguida de nanofiltração com membranas,” Pesquisa Agropecuária Brasileira, vol. 46, pp. 633–638, 2011.

Agência Nacional do Petróleo, Gás Natural e Biocombustíveis, Fundação Sistema Estadual de Análise de Dados, “São Paulo lidera produção de etanol no país,” SEADE, July 16, 2022. Available: https://www.seade.gov.br/saopaulolideraproducaodeetanolnopais/#:~:text=Das%20360%20unidades%20autorizadas%20pela,%25%20do%20total%20do%20Brasil.

R. P. Serrano, Biogas process simulation using Aspen Plus, Master’s thesis, Syddansk Univ., 2010.

C. M. T. Soares, A. Feiden, and S. G. Tavares, “Factors influencing the anaerobic digestion process in biogas production,” Nativa, vol. 5, pp. 522–528, 2017.

C. F. Carniato, G. F. Lopes, and L. M. M. Paraíso, “Modelagem e simulação da produção de biogás a partir da vinhaça de uma destilaria de etanol,” in Congresso Brasileiro de Engenharia Química, Uberlândia, MG, 2019.

C. R. Tunes, Produção de biogás a partir da digestão anaeróbica de efluentes orgânicos em reator UASB, Master’s thesis, Fed. Univ. Tocantins, 2017.

Y. Li et al., “Composition and toxicity of biogas produced from different feedstocks in California,” Environmental Science & Technology, vol. 53, no. 19, pp. 11569–11579, 2019.

Additional Files

Published

Issue

Section

Categories

How to Cite

Accepted 2024-12-03

Published 2025-01-10